Aluminum composite sheet suppliers provide essential materials widely used in construction, signage, and architectural projects. These suppliers offer panels made of two thin aluminum sheets bonded to a core, typically polyethylene or fire-retardant material, balancing durability and lightweight properties.

Choosing a reputable supplier ensures access to high-quality panels with consistent performance, weather resistance, and ease of fabrication. Many suppliers also provide options tailored for specific needs, such as fire-resistant cores or recycled content.

With the variety of products and technical specifications available, selecting the right aluminum composite sheet supplier can impact both project efficiency and final results. Understanding their offerings helps professionals make informed decisions quickly.

Overview of Aluminum Composite Sheet Suppliers

Aluminum composite sheet suppliers provide a variety of panel types, certified quality, and factors to consider when choosing a supplier. These elements define the materials’ usability across industries such as construction, signage, and architecture.

Types of Aluminum Composite Sheets Offered

Suppliers typically offer panels with different core materials. The most common type is aluminum sheets bonded to a polyethylene or fire-retardant mineral core. Fire-retardant cores enhance safety for exterior cladding applications, while standard polyethylene cores are often used in signage and indoor projects.

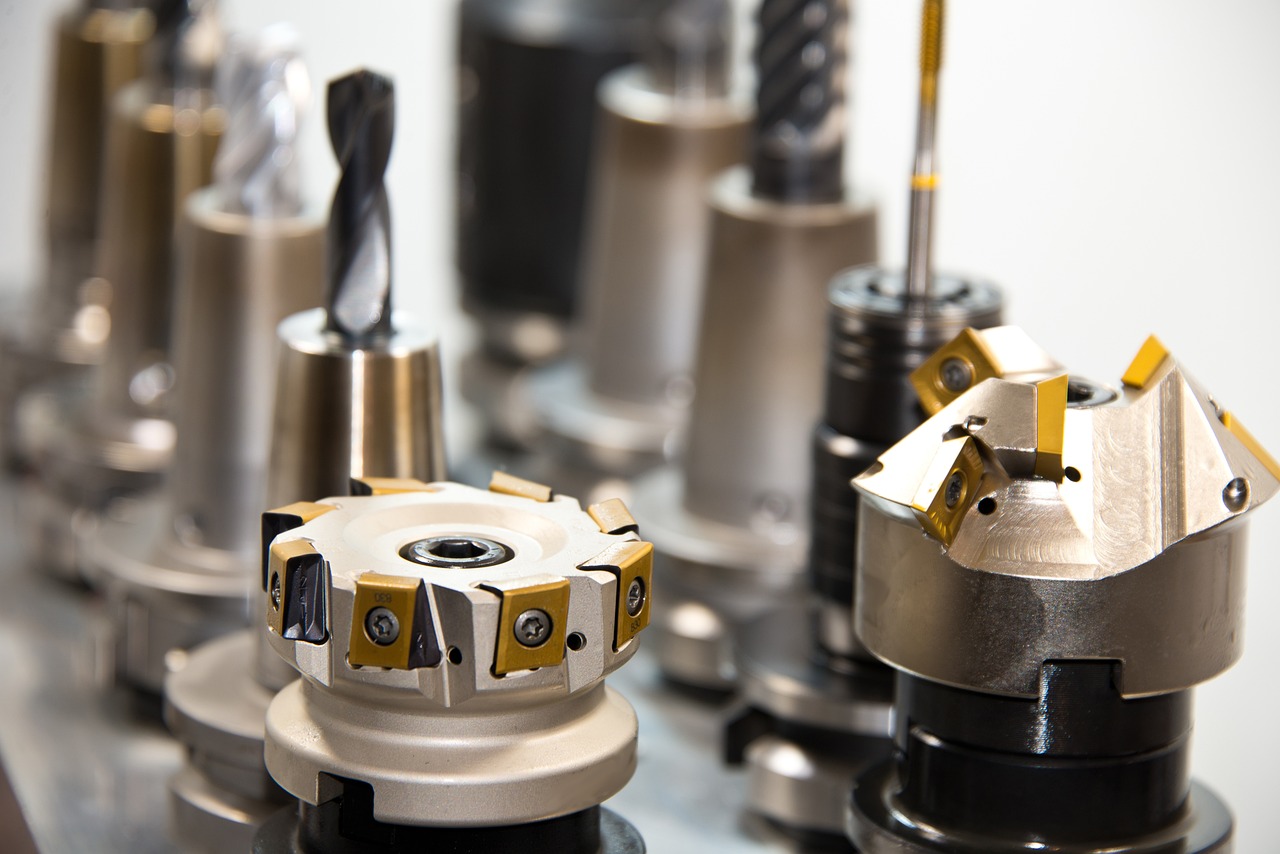

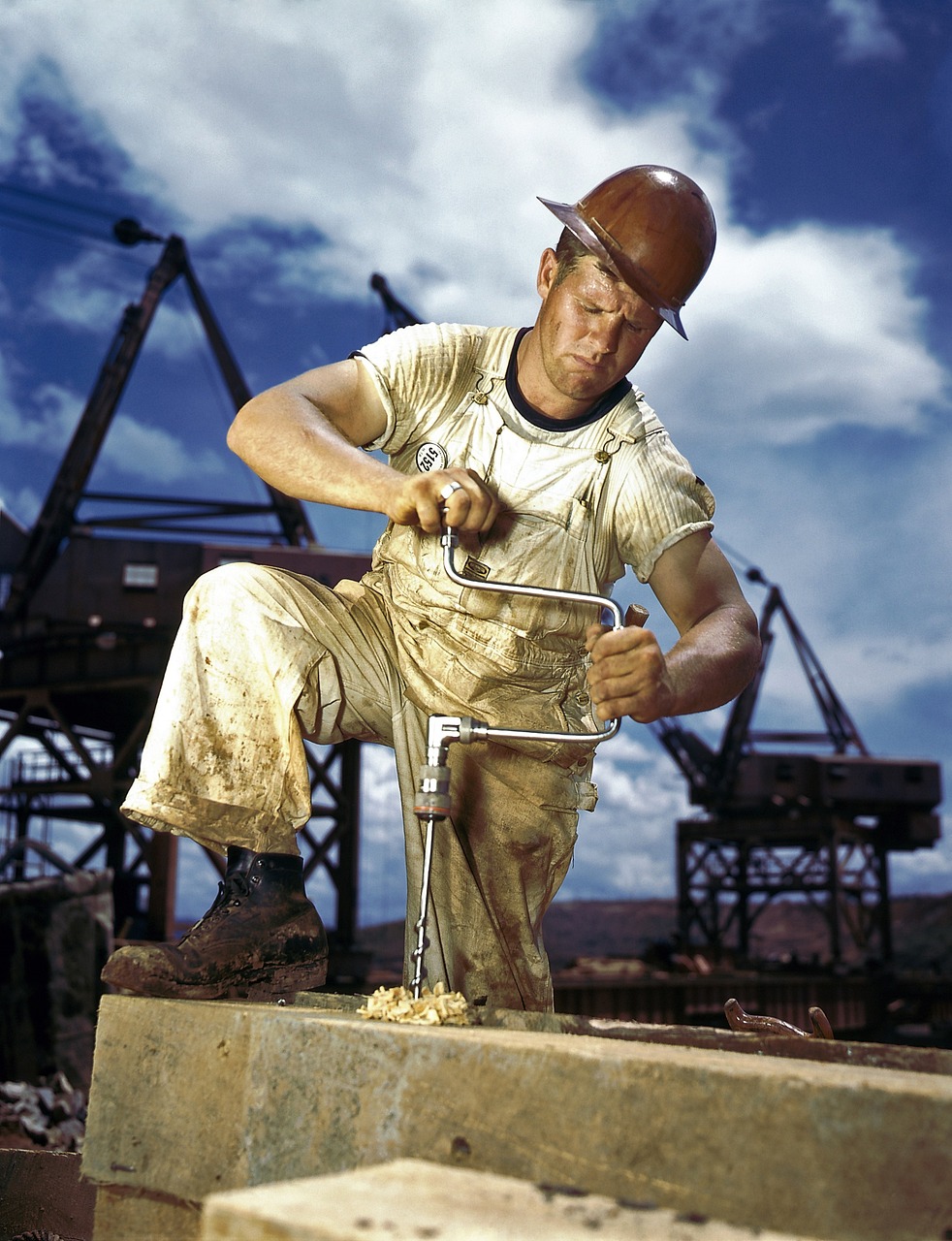

Sheets vary in thickness, surface finish, and color options. Pre-painted aluminum sheets come with protective coatings for durability and aesthetics. Some suppliers provide custom fabricated solutions like cutting, routing, or CNC machining to match project specifications precisely.

Industry Certifications and Standards

Reliable suppliers comply with national and international certifications related to fire safety, environmental impact, and material quality. Certifications such as ASTM, EN, or ISO standards ensure panels meet strict criteria for flammability, durability, and structural integrity.

Fire-retardant ratings are critical in building applications to comply with local safety regulations. Environmental certifications may include recyclability or low VOC emissions during manufacturing. These standards help maintain quality and safety across various applications.

Supplier Selection Criteria

When selecting a supplier, key factors include product quality, manufacturing capabilities, and service options. Quality depends on material specifications, consistent coatings, and core compositions that meet project demands.

Manufacturing flexibility, including thickness variations and processing services like cutting and anodizing, is essential for custom orders. Supplier reliability also hinges on timely delivery, technical support, and compliance with safety certifications. Price competitiveness is considered, but quality and certifications often weigh more heavily in critical applications.

How to Choose the Right Aluminum Composite Sheet Supplier

Selecting the right supplier involves careful scrutiny of their reliability, the quality of their products, and the pricing and delivery timelines they offer. Each factor plays a critical role in ensuring project success and meeting technical specifications.

Assessing Supplier Reliability

Reliability starts with a supplier’s reputation in the market. Established suppliers tend to have verified credentials and a track record of meeting deadlines and product specifications consistently.

It is important to check for certifications from recognized bodies to confirm compliance with industry standards. Customer reviews and testimonials can provide insight into their service quality and responsiveness.

Suppliers who maintain open communication and provide clear documentation about their products and processes demonstrate professionalism. Reliability also includes after-sales support, including handling logistics and addressing issues quickly.

Evaluating Product Quality

Product quality is a non-negotiable element in choosing an aluminum composite sheet supplier. The supplier should offer panels that conform to international quality standards such as ISO or ASTM.

Materials must be durable, energy-efficient, and fire-resistant as required by the project scope. Attention to fabrication details like core materials, coating finishes, and thickness consistency ensures longevity and proper performance.

A supplier providing product samples or detailed technical datasheets supports informed decision-making. The ability to customize sheets to specific size and finish requirements is also beneficial.

Comparing Pricing and Lead Times

Cost effectiveness is important but should not override product and service quality. Suppliers offering transparent pricing without hidden fees help avoid budget surprises.

Comparing quotes involves looking beyond base prices to factors like volume discounts and value-added services. Shorter lead times are crucial for meeting project schedules and minimizing delays.

A reliable supplier must provide accurate delivery estimates and have contingency plans for unforeseen disruptions. Flexibility in order quantities and shipping options can also improve project efficiency.