Installing rain gutters requires specific tools designed to ensure accuracy, durability, and efficiency. The essential rain gutter installation tools for gutter installation include punches, crimpers, saws, and specialized pliers that help shape, fit, and secure gutters correctly. Having the right selection simplifies the process and improves the quality of the finished system.

Those working on gutters need tools that handle metal cutting, shaping, and fastening with ease. Lightweight and durable options are preferred to reduce fatigue and maintain precision throughout the job.

Proper tools also help avoid common installation errors that can lead to leaks or improper water drainage. Whether for a professional installer or a homeowner tackling a DIY project, equipping oneself with the correct tools is a key step toward a reliable rain gutter system.

Essential Rain Gutter Installation Tools

Successful gutter installation depends on precise measurement, accurate cutting, secure fastening, and safe working conditions. Each of these aspects requires specific tools designed to handle their unique challenges effectively.

Measuring and Marking Tools

Accurate measurements are critical to ensure gutters fit perfectly along roof edges and direct water properly. Measuring tapes with clear markings and locking mechanisms are fundamental.

Levels are equally important; they ensure gutters slope correctly to guide water flow toward downspouts. Marking tools such as pencils or chalk help outline cutting points and bracket placements before installation begins.

A combination square or straight edge can further assist in aligning gutters and brackets. Precision in this phase avoids costly mistakes and rework.

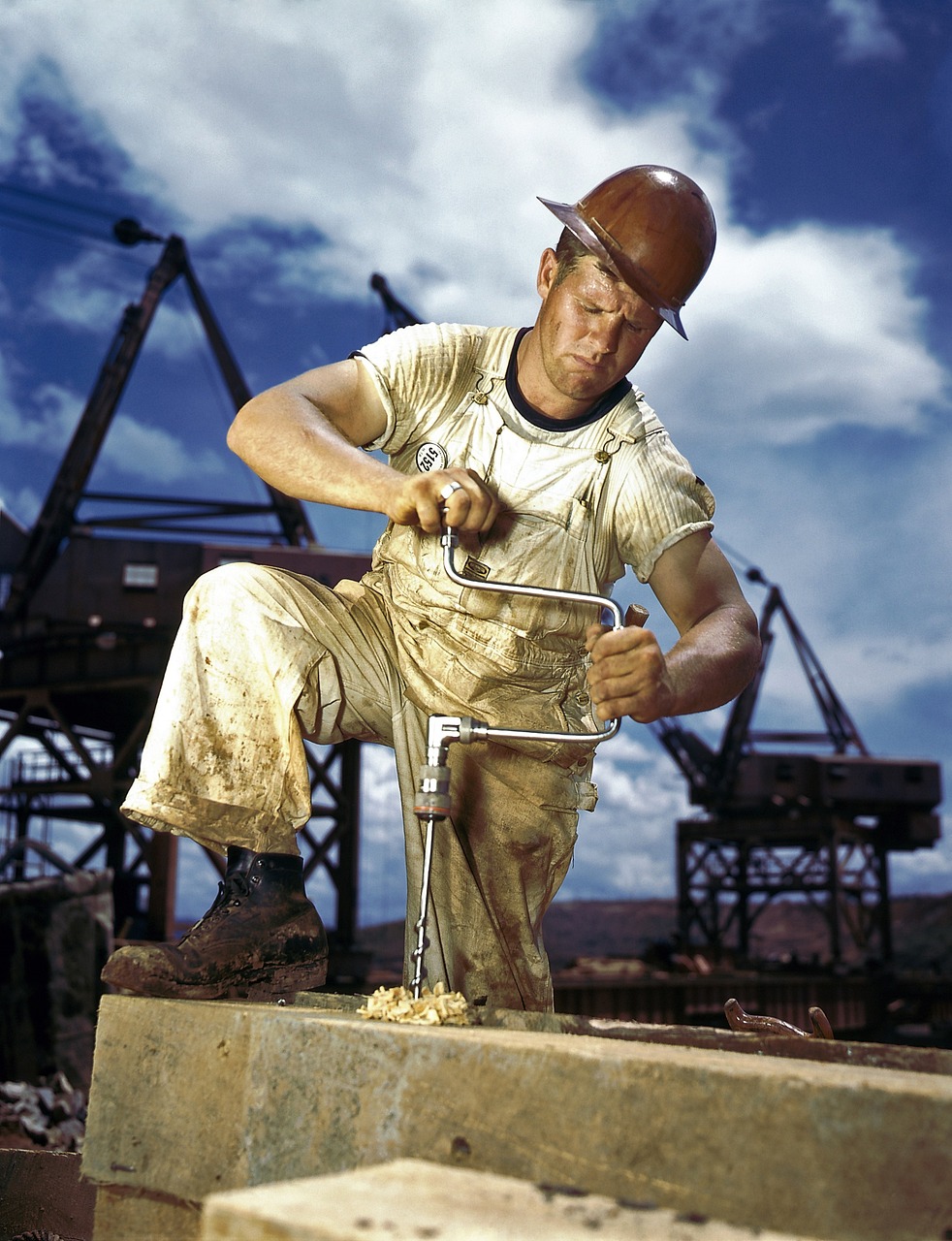

Cutting and Shaping Equipment

Gutters typically need to be cut to size and shaped to fit corners or deviations in the roofline. Tin snips are common for cutting small aluminum or steel gutters due to their ease of use and precision.

For longer, straight cuts, a hacksaw or power saw with a metal-cutting blade provides cleaner results. Crimpers are essential for shaping gutter ends, corners, and seams for assembly.

Some professionals use specialized gutter machines for custom shaping during large jobs. Proper cutting and shaping tools reduce the risk of damage and ensure smooth water flow.

Fastening Devices

Fastening gutters securely to fascia boards is vital for durability and function. Drill drivers or screw guns speed up the installation process when attaching brackets, hangers, and downspouts.

Stainless steel or galvanized screws resist rust, making them preferable for outdoor use. Bracket placement must be precise to maintain gutter alignment and support.

Sealants and rivets may be used to reinforce joints and prevent leaks. Proper fastening increases the gutter system’s longevity and stability during weather exposure.

Ladders and Safety Gear

Working at heights requires reliable ladders and safety equipment to prevent injuries. Extension ladders should be tall enough to reach rooflines comfortably and have slip-resistant feet.

Ladder stabilizers or stand-offs help protect gutters and provide stability on uneven surfaces. Using work gloves protects hands from sharp edges and rough materials.

Safety harnesses may be advisable for steep or high roofs. Maintaining secure footing and protective gear is essential throughout installation to avoid accidents.

Accessory Tools and Equipment

Accessory tools and equipment play a crucial role in ensuring a proper and durable gutter installation. These items aid in sealing joints, preventing clogs, and customizing the system to specific building requirements.

Sealants and Applicators

Sealants are essential to prevent leaks at gutter joints and seams. High-quality silicone or polyurethane sealants provide strong waterproof bonds that resist weather and temperature changes.

Applicators include caulking guns and specialized nozzles designed for precise, controlled application. Proper use of these tools ensures an even seal without excess material that can create mess or weaken adhesion.

Technicians often carry multiple sealant types and applicators to match different metal surfaces and joint designs. Compatibility with gutter materials like aluminum, copper, or steel is important when selecting sealants.

Debris Removal Tools

Clog prevention extends gutter system life and maintains water flow. Debris removal tools include gutter scoops, small shovels, and wire brushes designed to extract leaves, twigs, and dirt from interior surfaces.

Cleaning accessories may also feature lightweight extension poles to reach difficult areas safely. Some use specialized vacuum systems to remove buildup without disturbing surrounding shingles or siding.

Regular use of these tools reduces the risk of water damage caused by blockages and overflows, making debris removal a key maintenance and installation step.

Specialty Gutter Attachments

Specialty attachments customize gutter functionality and simplify installation tasks. Examples include downspout crimpers and outlet punches that shape and secure downspout sections effectively.

Gutter guards, screens, and leaf filters prevent debris intrusion while allowing water flow. These attachments reduce cleaning frequency and protect the overall system from damage.

Other equipment such as hangers, brackets, and expansion tools help tailor gutter fits for different rooflines and weather conditions. Using the right attachments ensures precise installation and long-term performance.